What Is an Integrated Sink? Discover the Pros, Cons & Best Material Choices

Introduction

Looking for answers about integrated sinks? You’re in the right place.

At Cpingao, we agree that choosing the right bathroom or kitchen fixture is essential for a stylish and functional home.

We promise to clearly explain what an integrated sink is, helping you understand its advantages and disadvantages, and how to choose the best material.

Follow this guide to confidently decide if an integrated sink fits your space and needs.

You may also be interested in What Are Integrated Sinks Made Of and Integrated Bathroom Sink vs Undermount Sink.

1.What Is an Integrated Sink?

An integrated sink refers to a product where the sink and countertop are formed as a single, unified piece.

Unlike traditional sinks that are mounted above or below the countertop, the integrated sink is directly molded into the counter, using the same material throughout. This means the sink is not an added component but a seamless extension of the surface itself.

Currently, there are two main manufacturing methods for integrated sinks: one-piece molding and precise joining. Both aim to achieve a smooth, continuous appearance.

Integrated sinks are becoming increasingly popular choices in bathrooms and kitchens due to their clean aesthetics and practical benefits.

2.Advantages of Integrated Sinks

Integrated sinks offer several practical and aesthetic benefits, making them ideal for modern environments such as hotels, hospitals, and high-end residential spaces:

- Seamless and Hygienic Design

Integrated sinks feature a smooth, joint-free structure that eliminates the hygiene issues common with traditional undermount or overmount sinks.

There are no gaps or seams where mold, grime, or dirt can accumulate, making them especially suitable for spaces with strict cleanliness standards, such as healthcare facilities, luxury hotels, and finely finished homes.

- Easy to Clean and Maintain

The surface of an integrated sink is typically made from non-porous materials such as solid surface or quartz stone, which are highly stain-resistant and impermeable.

These materials do not easily absorb water stains or foster mold, making cleaning simple and efficient with just a wipe.

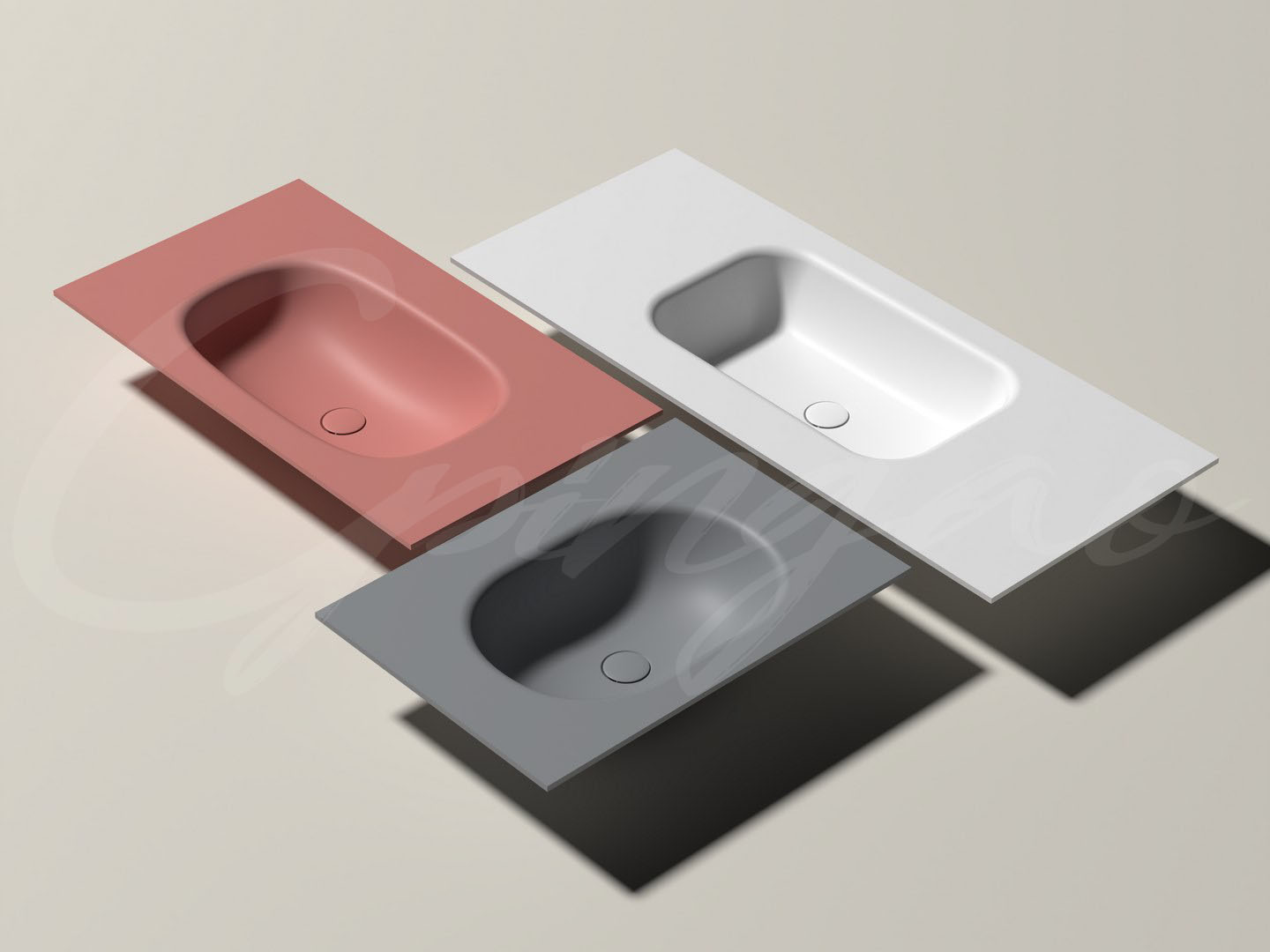

- Highly Customizable

Integrated sinks offer strong flexibility in design, accommodating a wide variety of spaces.

Their size, shape, color, and even edge details can be tailored to meet the specific needs of a project.

This makes them an excellent solution for engineering clients such as hotels, apartments, and commercial facilities that require bespoke installations.

3.Disadvantages of Integrated Sinks

While integrated sinks bring a sleek and modern touch to bathroom and kitchen design, they also come with certain limitations that are important to consider before making a purchase decision—especially for custom or large-scale projects.

- High Manufacturing and Transportation Costs

Due to the complex production process, especially when using materials like solid surface or artificial stone, integrated sinks typically have a higher manufacturing cost than conventional sink-countertop setups.

This is even more apparent with custom-made designs, where the cost can far exceed that of standard above-counter or undermount sink combinations.

The production precision required for seamless molding contributes significantly to the pricing.

- Challenging to Repair or Replace

Unlike traditional sinks that can be replaced individually, integrated sinks offer no option for partial replacement.

If the basin cracks, chips, or sustains any form of damage, it’s often impossible to repair just the sink area.

In most cases, the entire countertop must be replaced, which not only increases the repair cost but also causes more disruption during maintenance.

This is a key consideration for homeowners or businesses that prioritize long-term serviceability.

- Difficult to Transport with High Risk of Damage

The one-piece structure of integrated sinks results in a larger, heavier product, which requires special care in packaging, transport, and installation.

Improper handling can easily cause cracks, corner chips, or structural damage.

This makes logistics more complex and increases the need for professional delivery and installation teams, especially when dealing with larger-scale or high-end projects.

4.What materials of integrated sink can be chosen?

Solid Surface

Features:

Solid surface is a non-porous material that can be thermoformed into a seamless structure.

It offers a smooth, skin-friendly finish that's easy to clean and completely hygienic. Minor scratches and stains can be repaired through simple sanding.

Advantages:

Highly customizable in shape, color, and size, solid surface is ideal for projects with tailored design needs.

It is easy to maintain, feels pleasant to the touch, and is environmentally friendly and bacteria-resistant, making it suitable for sterile settings such as hospitals and airports.

Disadvantages:

The cost is relatively high, and in the case of severe localized damage, the material cannot be repaired—the entire countertop may need replacement.

Quartz Stone

Features:

Quartz stone is known for its high hardness and excellent resistance to wear and scratches.

It closely resembles natural stone in appearance.

Most integrated sink setups use a cut countertop combined with an undermount or mid-mount basin, though some manufacturers now support molded seamless designs.

Advantages:

Quartz stone offers a high-end look with strong stain and scratch resistance, making it ideal for heavy-use environments while maintaining a luxurious feel.

Disadvantages:

It is difficult to achieve a fully seamless integration, as most designs rely on joined components.

Additionally, quartz is heavy and complex to process, which can increase manufacturing and installation challenges.

Ceramic

Features:

Ceramic sinks are fired at high temperatures and finished with a glazed surface.

Some designs feature an integrated basin and countertop, molded as a single unit.

Advantages:

Ceramic is heat-resistant and resistant to acids and alkalis. The surface is hard, smooth, and bright white, giving a clean and elegant appearance.

It also offers a more budget-friendly option compared to other materials.

Disadvantages:

Despite its durability, ceramic is fragile and may crack or break upon impact, especially at the corners or edges, requiring careful handling during use and installation.

Stainless Steel

Features:

Stainless steel integrated sinks are typically created using a welded one-piece construction process, ensuring a durable and seamless structure.

Advantages:

This material is antibacterial, corrosion-resistant, and easy to clean, making it a top choice for kitchen environments where hygiene and durability are critical. Its industrial appeal also suits modern minimalist designs.

Disadvantages:

Stainless steel can feel cold to the touch and tends to show fingerprints and water spots easily, which may require frequent wiping to maintain its clean appearance.

Concrete

Features:

Concrete integrated sinks are made using a hand-poured casting process, allowing for highly individualized and artistic designs.

Advantages:

Concrete offers a strong sense of design and a distinctive texture that brings character to any space.

Its raw, industrial aesthetic makes it a favorite for modern or custom interiors.

Disadvantages:

Concrete is prone to cracking and water absorption if not properly sealed. It requires careful glazing and regular maintenance.

Additionally, it tends to be more expensive due to its craftsmanship and upkeep needs.

Conclusion

This article explained what an integrated sink is, along with its pros, cons, and material choices like solid surface, quartz, ceramic, stainless steel, and concrete.

Many readers are most interested in knowing which materials are best, how easy it is to clean, and whether repairs are possible.

These questions are key for making smart, long-term decisions.

We hope this guide from Cpingao helps you better understand integrated sinks and choose the right solution for your project.

Welcome to know more detailed information about products in Cpingao: